From Cobots to Humanoids: The Robotics Trends Every Business Must Know in 2026

By Jalaj Shah

September 8, 2025

Quick Executive Summary

In 2026, collaborative robotics and humanoid advances are reshaping business operations. This article explains what cobots are, how cobot automation compares to traditional industrial robots, and why cobot integration is delivering rapid ROI across manufacturing, logistics, and services. It also examines welding cobot applications, human-robot collaboration, the rise of humanoid platforms, and concrete deployment strategies for CEOs and CTOs. Data-driven insights and case studies guide decision-making.

The robotics landscape in 2026 presents a pivotal opportunity for businesses seeking productivity, resilience, and competitive differentiation. Collaborative robots, commonly called cobots, have evolved beyond novelty tools into practical assets for assembly, welding, inspection, and material handling. At the same time, humanoid and service robots are crossing experimental thresholds and entering constrained commercial deployments. This article presents a structured, data-driven examination of these trends, with precise definitions, quantitative indicators, trusted case studies, and clear guidance for enterprise leaders. It uses practical examples to illustrate how cobot robotics and humanoid platforms can be integrated into operations, and what business leaders must plan for to capture value.

What Is a Cobot? Definition and Core Capabilities

A cobot (collaborative robot) is a robot engineered to work safely alongside human workers. Unlike traditional industrial robots that require guarding and isolation, a cobot robot incorporates force-limiting actuators, sensors, and safety software that enable human-robot collaboration in shared workspaces. Typical cobot arms have user-friendly programming interfaces, modular end-effectors, and compact footprints. Key capabilities include precise repeatability, flexible reprogramming for new tasks, and sensor-driven motion control that reduces injury risk. Cobots are especially suited to repetitive or ergonomically demanding tasks, such as machine tending, parts insertion, packaging, and cobot welding, where steady path following and consistency yield measurable quality and throughput gains.

Cobot robotics emphasises accessibility: operations teams can often reconfigure a cobot arm for a new process in hours rather than weeks. This operational agility is core to cobot automation strategies for small-to-medium enterprises as well as large manufacturers.

Cobot vs Robot: When to Choose Collaborative Robotics Over Traditional Automation

Understanding cobot vs industrial robot tradeoffs is essential for strategic automation decisions. Industrial robots excel at high-speed, high-payload continuous tasks and typically perform best when isolated inside safety cages. They deliver maximum throughput for long-run, dedicated production lines. Collaborative robots, by contrast, trade some speed and payload for human-safe interaction, rapid redeployment, and lower up-front costs. A well-planned cobot integration reduces time-to-value and enables incremental automation: pilot with a single collaborative robot, demonstrate ROI, then scale.

Cost profiles differ: the total delivered cost of a cobot solution often includes the arm, end-effector, vision system, and integration, but still commonly undercuts a full industrial cell once safety infrastructure is considered. For welding cobot applications, cobot welders offer precise path control for repetitive seams and complement skilled welders rather than replacing them. For heavy, continuous body-shop welding, industrial cells remain preferable.

Statistics Report: Market Size, Growth, and Adoption Metrics

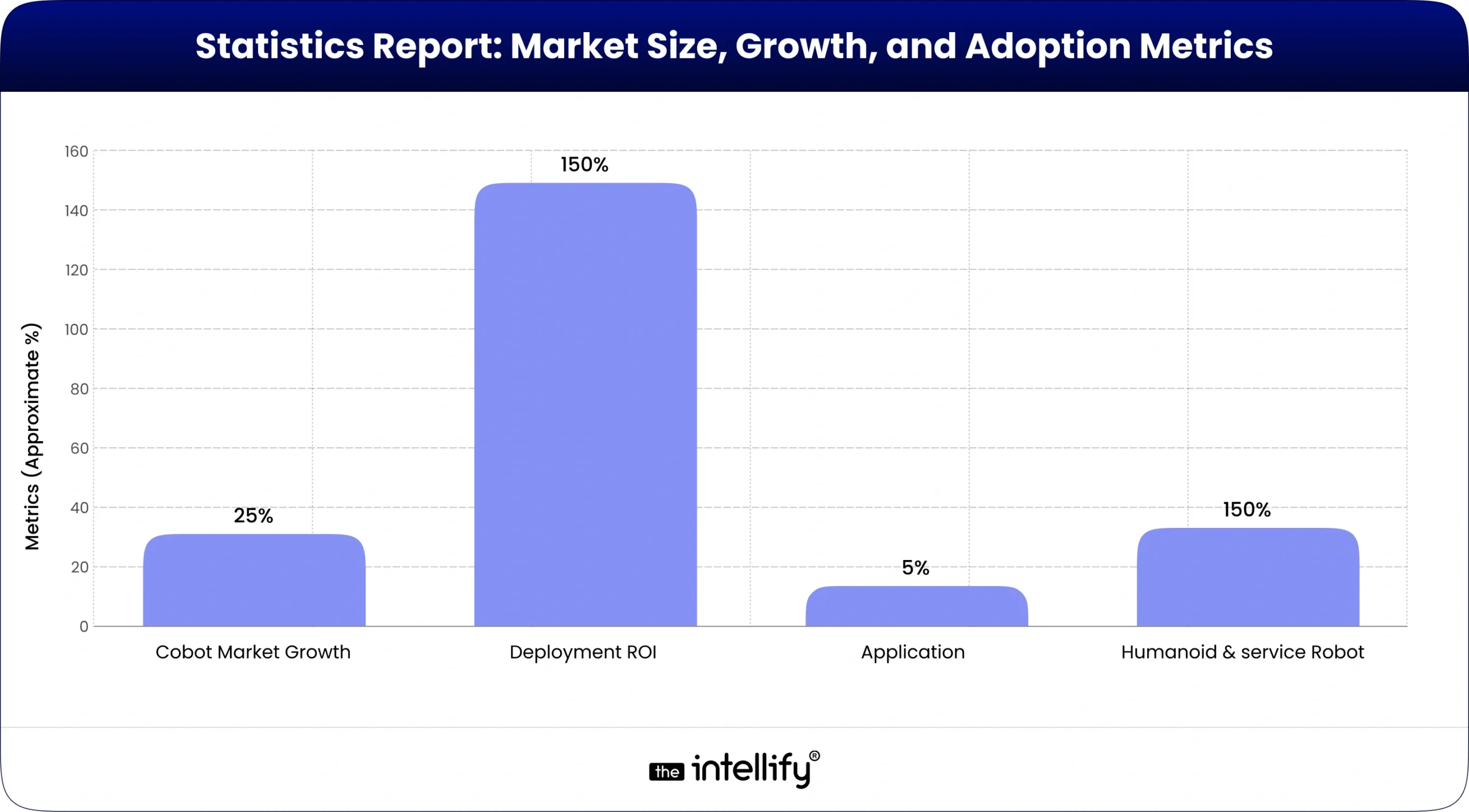

- Collaborative robotics market growth: strong double-digit growth driven by manufacturing and logistics. Year-over-year installations of cobot arms have increased as unit prices declined and programming became more accessible.

- Deployment and ROI: early adopters report payback periods under 12 months for common cobot automation use cases such as machine tending and quality inspection. Productivity uplifts often range from 20% to 200% depending on baseline efficiency and task complexity.

- Application distribution: top cobot applications by volume include assembly, pick-and-place, packaging, machine tending, and welding. Automotive and electronics sectors continue to represent a large share of deployments, while small manufacturers are increasing uptake for flexible cell automation.

- Humanoid and service robotics: growth rates for service and humanoid robots exceed industrial robot growth in percentage terms, reflecting expanding non-manufacturing use cases in logistics, healthcare, and services. Unit economics and per-unit costs vary widely across form factors and capabilities.

These statistics reflect aggregated industry reporting, supplier disclosures, and independent market analyses and should be interpreted as directional guidance for planning.

Real-World Examples and Case Studies: Proven Outcomes

Below are anonymised and representative case studies that distil common outcomes from multiple deployments across industry. Each represents a typical deployment pattern and measurable results.

Case Study: Cobot Machine Tending in a Small Moulder

A small plastics moulder integrated a cobot arm for injection moulding machine tending and inline inspection. The cobot handled loading, unloading, and simple dimensional checks using an attached vision module. Outcomes: cycle time reduction through parallel loading, a 3-4x improvement in parts-per-hour throughput on the tended machines, and redeployment flexibility to other presses during peak demand. The investment delivered a return in under 12 months due to labour savings and higher yield.

Case Study: Cobot Welding in a Fabrication Shop

A mid-size fabrication shop automated repetitive MIG welds with a cobot welding cell. The cobot performed consistent tack and fillet welds along straight seams; skilled welders focused on complex joints and quality checks. Outcomes: improved weld consistency, reduced rework, and higher employee satisfaction as manual strain decreased. The welding cobot also enabled the shop to accept small-lot jobs with predictable margins.

Case Study: Dual-Arm Collaborative Automation at an Appliance Line

An appliance manufacturer implemented dual-arm collaborative robots for inspection and final assembly tasks that required gentle handling and precise alignment. Dual-arm cobots handled part positioning while workers completed wiring and final checks. Outcomes: defect rates declined, throughput increased, and ergonomics improved for assembly staff. The plant reported rapid scaling of similar cobot tasks across adjacent lines.

Cobot Arm Design, Accessories, and Integration Considerations

Selecting the right cobot arm requires aligning technical specifications with the intended collaborative robot applications. Key attributes include reach, payload, repeatability, and degrees of freedom. For tasks such as precision assembly or pick-and-place, a 6-axis cobot arm with sub-millimetre repeatability is often appropriate. For heavier machine tending and material transfer, choose a collaborative robot arm with a higher payload and a larger reach. Consider the following when evaluating:

- Payload and Reach: Match arm specs to the heaviest part plus tooling weight. Allow margin for future accessories.

- Repeatability and Speed: Welding cobot applications depend on steady repeatability and smooth motion to avoid heat-related defects. Specify repeatability tolerances appropriate to the weld profile.

- End-effectors and Cobot Accessories: A vibrant ecosystem of grippers, vacuum cups, force/torque sensors, and welding torches expands what a single cobot can accomplish. Ensure that the cobot company supports third-party accessories and provides standardised mounting and electrical interfaces.

- Safety and Sensors: Integrated safety-rated torque sensing, light curtains, and vision-based human detection are essential for human-robot collaboration. Confirm safety certifications and firmware update policies.

- Software and Integration: Favour cobot platforms with open APIs and support for common industrial fieldbuses and PLCs. Ease of integration reduces system integration labour and long tail costs. Evaluate simulation tools and digital twin support for offline programming and validation.

The right combination of arm, accessories, and integration approach reduces downtime, accelerates deployment, and improves long-term utilisation. Collaboration between operations, engineering, and the chosen cobot company is critical to avoid scope creep and misaligned expectations.

Choosing a Cobot Company and Working with Collaborative Robot Manufacturers

Selecting a vendor is both technical and strategic. Established collaborative robot manufacturers often offer proven hardware, an ecosystem of certified integrators, and a broad accessory catalogue. When evaluating a cobot company or integrator, consider:

- Ecosystem and Support: Does the manufacturer provide local service, spare parts, and training? How robust is their partner network for system integration?

- Total Cost of Ownership: Compare warranty, maintenance plans, and software licensing. A lower upfront price can be offset by expensive proprietary upgrades or limited accessory choices.

- Interoperability: Confirm that the collaborative robots can be orchestrated with existing PLCs, MES, and fleet management systems.

- Proof of Concept and References: Ask for short reference projects with similar collaborative robot applications and performance metrics.

A successful vendor relationship is often as important as the hardware specification. Vendors that offer clear documentation, training, and a pathway to scale help organisations minimise surprises during broader deployment.

Collaborative Robotics in the Automobile Industry and Complex Assembly

The automobile sector remains a pivotal adopter of collaborative robotics. Collaborative robot arms are used for screwing, fitting, testing, and secondary assembly, where flexibility and speed of retooling matter. In variable-model production lines and low-volume high-mix operations, cobots shine by enabling rapid changeovers. Collaborative robots in manufacturing often operate alongside humans on tasks such as harness routing, sensor installation, and interior trimming, where tactile sensitivity is critical.

In welding-intensive stations, hybrid strategies prevail: industrial robots provide high-speed spot welding on primary body seams, while cobot welding cells address secondary seam welding and small-batch tasks. Cobot integration in automobile plants allows a nuanced distribution of tasks that optimises throughput while maintaining quality across model variants.

Expanding Cobot Automation Beyond Manufacturing

Cobot applications extend into logistics, healthcare, agriculture, and services. In logistics, cobot arms loaded on modular workstations support sorting, order fulfilment, and returns processing. In healthcare, cobot arms assist in laboratory automation, sample handling, and repetitive sterilisation tasks, reducing contamination risk and improving throughput. Agricultural pilots deploy cobot-guided arms on mobile platforms for selective picking and pruning where delicate handling is required.

These non-traditional deployments emphasise collaboration with human specialists: in labs, researchers work alongside cobots for precise pipetting; in farms, operators guide cobots to identify ripe fruit; and in warehouses, pickers collaborate with cobot arms for mixed-case fulfilment.

Technology Enablers: AI, Vision, Connectivity, and RaaS

Four converging technologies enable contemporary cobot and humanoid capabilities:

- AI and vision: On-arm vision, sensor fusion, and machine learning enable parts recognition, dynamic path planning, and adaptive gripping for variable products.

- Connectivity and edge compute: Edge processing supports millisecond response times for safety and motion control, while cloud services enable fleet analytics and over-the-air updates.

- Modular end-effectors and accessories: A broad ecosystem of grippers, force-torque sensors, and welding torches allows rapid retooling of cobot arms to meet different tasks.

- Robotics-as-a-Service (RaaS): Subscription models lower cost barriers by converting capex to opex and enabling pilot programs without large upfront capital.

These enablers simplify cobot integration and create measurable business outcomes when combined with disciplined change management.

Deployment Guidance for CEOs, CTOs, and COOs

- Start with a clear business objective: target repetitive, high-variability, or ergonomically risky tasks for early pilots. Use measurable KPIs such as cycle time, defect rate, and labour hours saved.

- Choose modular cobot solutions: prioritise systems with standardised interfaces and a wide array of cobot accessories to reduce integration complexity.

- Invest in skills and governance: train operators on safe human-robot collaboration, create cross-functional teams for continuous improvement, and define governance for remote updates and security.

- Scale plan: design cells that can be replicated, instrument data collection early, and favour vendors that support fleet management and edge/cloud analytics.

- Consider RaaS where capital is constrained: subscription models accelerate adoption and permit rapid iteration with limited financial exposure.

- Safety and standards: align with industry safety practices and implement redundant sensing and lockout procedures for collaborative robot applications.

Following these steps helps executives prioritise automation investments, manage workforce impact, and ensure responsible, high-return deployments.

Cost and ROI Considerations for Collaborative Robotics

When modelling cobot investments, account for the capital cost of the arm, gripper, or welding torch, vision and safety sensors, integration labour, and ongoing maintenance. Include soft benefits such as reduced injury claims, improved quality, and faster time-to-market for new SKUs. Typical pilot projects show payback within 6–18 months, depending on labour cost, utilisation, and task complexity. For welding cobot projects, measure reduction in rework and scrap alongside throughput gains.

Risk Management, Workforce Transition, and Change Management

Effective automation programs combine technological deployment with human-centric change management. Transparent communication about job redesign, reskilling pathways, and safety protocols mitigates workforce concerns. Upskilling technicians to program and maintain cobot arms is a high-value investment. Cross-training increases resilience and reduces single-point failures when robot maintenance or troubleshooting is required.

Safety Standards, Compliance, and Liability Considerations

Safety remains paramount for collaborative robot applications. Compliance with international safety standards and thorough risk assessments is non-negotiable. Enterprises should follow established risk assessment methodologies, implement multiple layers of safety (hardware interlocks, software limits, and operator training), and document mitigation measures. In addition to ISO standards, manufacturers and integrators provide specific risk assessments for cobot automation in welding and other high-energy tasks.

Insurers increasingly expect documented safety programs and evidence of operator training when underwriting automated facilities. Detailed maintenance plans and clear delineation of responsibilities between integrator and operator reduce exposure and streamline audits.

Implementation Timeline and Budget Template

A typical cobot pilot follows a compact timeline:

- Week 0–2: Problem definition, KPI selection, and vendor shortlisting.

- Week 3–6: Proof of concept and cell design; select end-effectors and safety systems.

- Week 7–10: Integration, programming, and test runs; operator training.

- Week 11–16: Pilot validation, KPI measurement, and scaling plan.

Budget items should include hardware, grippers/welding torches, vision modules, integration labour, safety equipment, spare parts, and training. Contingency for unforeseen integration work. Using RaaS can smooth budgetary constraints and accelerate learning cycles.

Research Directions and Long-Term Considerations

Research in cobotic control, human-aware planning, and dexterous manipulation continues to improve capability. Advances in learning from demonstration, force-feedback sensing, and tactile fingertips will broaden collaborative robot applications into finer manipulation tasks. Power-dense actuators and improved battery technologies will support more mobile and untethered human-collaborative platforms.

For executives, the strategic implication is to treat cobotics as a technology platform. Invest in modular infrastructure, talent development, and data strategy to be ready as robotic capabilities expand.

The Rise of Humanoids and Strategic Outlook

Humanoid and service robots are progressing from research labs into constrained commercial settings. Present deployments focus on repetitive support roles, material handling in warehouses, clinical assistance in healthcare settings, and public-service demonstrations. For businesses, three pragmatic takeaways apply:

- Evaluate complementary roles: consider humanoids for tasks where human form factor and mobility deliver unique advantages, such as navigating stairs or operating human-designed tools.

- Pursue narrow pilots first: pilot humanoid platforms in repeatable, bounded scenarios to measure throughput, safety, and total cost of ownership.

- Integrate with the automation ecosystem: combine cobot arms, autonomous mobile robots, and humanoids within a common orchestration and monitoring layer to maximise flexibility.

Humanoids will mature over the next decade, but their business adoption will follow a phased pattern driven by task fit, economics, and regulatory clarity.

Final Recommendations: A Leader’s Checklist

- Define one measurable problem to solve with a cobot in the next 90 days.

- Select a vendor ecosystem with modular cobot accessories and a strong support network.

- Design a pilot with clear KPIs and a documented scaling plan.

- Commit to workforce retraining and establish a robotics centre of excellence for knowledge transfer.

- Track energy and sustainability metrics tied to automation goals.

By following this checklist, leaders can turn robotics from a technical curiosity into a strategic capability that drives efficiency, quality, and employee well-being.

Conclusion

From cobots to humanoids, robotics will continue to reshape operational models. Collaborative robotics enables fast, safe, and cost-effective automation for many tasks, while humanoid platforms point toward future capabilities in mobility and service. Business leaders who pair clear objectives with disciplined pilots, workforce development, and an eye for complementary technologies will capture the greatest value. Automation should be treated as a continuous capability that scales across teams and sites rather than a one-off technology project.

FAQs

1. What is a cobot (what are cobots)?

A: A cobot is a collaborative robot designed to work safely alongside humans; cobots combine a flexible cobot arm, sensors, and intuitive programming for fast cobot integration on shop floors.

2. How are cobots different from industrial robots (cobot vs robot)?

A: Cobot vs industrial robot: cobots prioritize human-safe interaction, quick redeployment, and easier programming, while industrial robots deliver higher speed/payload in fenced cells.

3. Which collaborative robot applications deliver the fastest ROI?

A: Top collaborative robot applications with quick ROI are machine tending, pick-and-place, quality inspection, and cobot welding for repetitive seams.

4. Can cobot welding replace skilled welders (welding cobot/cobot welder)?

A: A welding cobot increases repeatability and reduces rework on straight or repetitive seams, but it typically complements, not fully replaces, skilled welders for complex welds.

5. How much does a cobot arm cost, and what are cobot accessories?

A: A typical cobot arm ranges widely by model; budget for the arm, vision, and cobot accessories (grippers, force sensors, welding torches) when planning the total cost of ownership.

6. What should I ask a cobot company before purchase (cobot company / collaborative robot manufacturers)?

A: Ask about integration support, spare parts, training, safety certifications, open APIs, and references from similar deployments when evaluating a cobot company or collaborative robot manufacturer.

7. How long does cobot integration take (cobot integration timeline)?

A: Simple cobot pilots can be deployed in weeks; a full cobot integration and scale plan typically follows an 8-16 week pilot, depending on safety, vision, and PLC integration needs.

8. Are industrial cobots safe for human-robot collaboration?

A: Yes, modern industrial cobots include force-limiting joints, vision and proximity sensors, and certified safety modes that enable safe human-robot collaboration when risk assessments and training are in place.

9. Which industries benefit most from cobot robotics (collaborative robots in manufacturing)?

A: Automotive, electronics, plastics, food packaging, and small-batch manufacturers are prime adopters; collaborative robots in manufacturing are also growing in labs, logistics, and healthcare.

10. How do I measure success for cobot projects (KPIs for cobot automation)?

A: Track KPIs such as cycle time reduction, throughput, defect rate, utilization, payback period, and labor hours saved to evaluate cobot automation success.

Written By, Jalaj Shah

The COO and Co-Founder of The Intellify. Jalaj enjoys experimenting with new strategies. His posts are fantastic for businesses seeking innovative development ideas. Discover practical insights from his engaging content.

Transforming Legacy Application Modernization with AI and Automation

Summary: Legacy Application Modernization helps businesses upgrade outdated systems while maintaining operational stability. Many enterprises face technical debt, scalability challenges, and security risks that limit growth. By combining AI-driven automation with structured modernization strategies, organizations can improve performance, strengthen compliance, and enhance user experience. The blog also covers legacy mobile app modernization, industry use cases, […]

Enterprise AI Strategy & Adoption: Step-by-Step Implementation Guide

Summary: In today’s fast-paced business environment, enterprise AI is no longer just a buzzword; it’s become essential. Its potential to reshape operations, enhance decision-making, and drive efficiency is making AI a crucial part of organizational strategies around the globe. In this guide, we’ll explore how businesses can methodically adopt AI, from crafting a solid strategy […]

AI in Healthcare Claims Processing: A Practical Implementation & ROI Guide

Summary: Healthcare claims processing is often slow, manual, and prone to costly errors. This blog breaks down how AI in healthcare helps reduce denials, speed up reimbursements, and improve revenue cycle performance. You’ll see how AI supports each step of the claims process, what benefits providers and insurers can expect, and what it takes to […]

Transforming Legacy Application Modernization with AI and Automation

Summary: Legacy Application Modernization helps businesses upgrade outdated systems while maintaining operational stability. Many enterprises face technical debt, scalability challenges, and security risks that limit growth. By combining AI-driven automation with structured modernization strategies, organizations can improve performance, strengthen compliance, and enhance user experience. The blog also covers legacy mobile app modernization, industry use cases, […]

Enterprise AI Strategy & Adoption: Step-by-Step Implementation Guide

Summary: In today’s fast-paced business environment, enterprise AI is no longer just a buzzword; it’s become essential. Its potential to reshape operations, enhance decision-making, and drive efficiency is making AI a crucial part of organizational strategies around the globe. In this guide, we’ll explore how businesses can methodically adopt AI, from crafting a solid strategy […]

AI in Healthcare Claims Processing: A Practical Implementation & ROI Guide

Summary: Healthcare claims processing is often slow, manual, and prone to costly errors. This blog breaks down how AI in healthcare helps reduce denials, speed up reimbursements, and improve revenue cycle performance. You’ll see how AI supports each step of the claims process, what benefits providers and insurers can expect, and what it takes to […]

0

+0

+0

+0

+Committed Delivery Leads To Client Satisfaction

Client Testimonials that keep our expert's spirits highly motivated to deliver extraordinary solutions.