-

-

- Supply Chain Management (SCM): Coordination of end-to-end flows of materials, information, and finances across global networks. Modern SCM tools (ERP, APS, WMS, TMS) aim to optimise inventory, demand forecasting, and logistics, while also managing supply chain risk.

-

- Digital Twin Technology: A digital twin technology is a dynamic virtual replica of a physical asset, process, or system that continuously integrates live data to simulate and predict outcomes. In SCM, digital twin technology creates a real-time, interconnected model of the entire supply chain, enabling scenario analysis and AI-driven optimisation.

-

- Industry Trends & Statistics: The digital-twin market is surging. McKinsey projects the global market to reach $125–150 billion by 2032 (30–40% annual growth). Maersk reports the supply chain digital twin segment will grow from $2.8B (2023) to $8.7B (2033) (CAGR ≈12%). E-commerce is exploding; DHL notes parcel volumes will hit 256 billion by 2027. Early adopters report major gains e.g., up to 30% better forecast accuracy and 50–80% fewer delays.

-

- Digital Twin Benefits: By integrating with SCM software as an “innovation layer,” digital twins enable real-time visibility, predictive planning, and dynamic optimisation. Companies simulate disruptions (‘what-if’ scenarios), optimise inventory buffers and capacity, and improve performance (e.g, on-time delivery) by up to 20–30%. They also support sustainability and decarbonization by modelling energy use and emissions.

-

- Governance & Best Practices: Scaling twins requires strong data governance, integration standards, and cross-functional teams. Experts advise setting a “North Star” roadmap of use cases, building standardised data pipelines, and using flexible cloud-based architectures. Break down silos (one central twin model), manage cybersecurity, and train skilled talent (data engineers, product owners) for agile development. Pilot quickly to prove value and iterate.

-

- Use Cases & Industries: Digital twins industries. In manufacturing, they optimize production and predictive maintenance (e.g., Rolls-Royce extended engine life by ~50%, saving 22M tons of CO₂). AI in logistics & supply and warehousing, DHL built a simulation twin to staff its warehouse, achieving 98% accuracy in shift planning. Retailers use twins for demand forecasting and inventory flow, improving fulfillment rates and cutting labor costs. Heavy industries (oil, mining, construction) use twins (via platforms like BCG X) to handle complexity, improving forecast accuracy by 30% and slashing delays by 50–80%. Healthcare/pharma and consumer goods benefit from synchronized cold chains and supplier networks.

- Summary: Digital twins are transformative and already here. They merge AI, IoT, cloud, and analytics to create “digital-first” supply chains that are more transparent, agile, and resilient. Companies adopting global SCM digital twins can expect significant efficiency, risk management, and sustainability gains.

-

Introduction

Modern supply chain management is under unprecedented pressure. Nearly 90% of customers now expect 2–3 day delivery, up from about half a decade ago. At the same time, volatile global events (pandemics, trade bottlenecks, labour shortages) have exposed vulnerabilities in global supply chain management. Wages for warehouse labour have surged (~30% from 2020–2024), and corporate fleets and production are more strained than ever. In response, leading companies are embracing digital transformation.

A key innovation is the digital twin, a virtual replica of the supply chain, which allows planners to test scenarios and optimise flows without disrupting reality. For example, McKinsey notes that some retailers have connected planning, inventory deployment, a nd transportation management via a digital twin, enabling dynamic, end-to-end optimisation. The following sections explore supply chain management, digital twins, and how to scale them globally, backed by data, case studies, and best practices.

What is Supply Chain Management?

Supply Chain Management (SCM) is the orchestration of all activities involved in getting products from raw material sourcing to the customer’s doorstep. It covers planning, procurement, manufacturing, inventory management, warehousing and distribution, and even returns. Effective SCM aims to deliver the right products at the right time at minimal cost, while managing supply chain risk (like supplier disruptions or demand spikes).

For example, SCM software tools (ERP systems, advanced planning, warehouse management, and transportation systems) help companies forecast demand, optimise inventory, and coordinate logistics and supply chain management across multiple partners. In many industries (manufacturing, retail, automotive, healthcare, construction, etc.), specialised supply chain management solutions are deployed – from Oracle or SAP suites to niche logistics software – to streamline processes. Green and sustainable supply chain management practices are also rising, as SCM now includes environmental considerations like reducing carbon footprints through optimised routes and energy use.

In summary, SCM is about the end-to-end supply chain process: sourcing materials, producing goods, storing inventory, and delivering items to customers. It relies on robust supply chain management systems and software modules (e.g., procurement systems, warehousing software, transportation planning, and risk management tools) to synchronise activities across suppliers, manufacturers, distributors, and retailers. This multi-tier network is complex, but advanced SCM tools aim to provide visibility and control over it.

What is a Digital Twin?

A digital twin is a living virtual model of a physical system, in this case, the supply chain, that continuously integrates real-time data. In practice, a digital twin leverages IoT sensors, cloud computing, AI, and analytics to mirror and monitor the physical world. For example, a shipping fleet’s twin might ingest GPS, weather, a nd fuel data to simulate voyage outcomes, or a factory twin might use machine sensor data to predict maintenance needs.

The World Economic Forum defines a digital twin as “a dynamic digital representation of an object or a system,” modelled by equations and data. Unlike static models or simple dashboards, digital twins actively evolve with live data: they “observe their physical environment through a network of sensors, learn from information, and continuously communicate” across devices and teams.

Digital twinning is not a standalone gadget; it’s a convergence of technologies. According to MIT Sloan Research, digital twins combine multiple enablers, sensors, cloud platforms, advanced analytics, simulation, and visualisation tools (even augmented/virtual reality) into a single framework.

Crucially, they act like smart, decision-making assistants. Digital twins can emulate human reasoning by running thousands of “what-if” scenarios to predict outcomes. They provide 360° visibility and traceability: managers can instantly see where bottlenecks or inventory variances might occur and test adjustments in the virtual model before touching the real supply chain. In effect, a digital twin becomes an “active and social” tool that continuously coordinates with both people and machines to optimise operations.

A key question often arises: What are digital twins in manufacturing or logistics? Simply put, they are sophisticated simulations built on live data. For example, Microsoft’s Azure Digital Twins service lets companies build detailed models of factories or supply networks. A twin can represent warehouses, trucks, production lines, or entire supplier networks. By feeding it near-real-time data (e.g., inventory levels, shipment GPS, or machine status), the twin dynamically models the current state of the supply chain.

Then AI algorithms are layered on the twin to provide predictive insights or autonomous decisions (sometimes called an AI digital twin). This digital-twin technology is transforming how businesses manage their operations and supply chain management enabling predictive maintenance, automated re-planning, and risk mitigation that were previously impossible.

Digital Twins in Supply Chain Management

In the context of SCM, digital twins serve as an innovation layer on top of traditional SCM software. Think of a digital twin as a sophisticated overlay that connects an ERP’s inventory data, a WMS’s storage status, a TMS’s shipping info, and supplier systems into one unified model. McKinsey notes that digital twins ingest real data from across the chain to simulate “potential situations and outcomes”.

For example, a company might use a digital twin to rapidly test how a supplier shortage and a port strike would affect its end-to-end flow, and then find the best alternate shipping routes and inventory plans. Because it’s fed by live data, the twin provides an up-to-date “single source of truth.” This real-time visibility lets planners see the impact of changes immediately, for example, how rerouting a shipment adds days and costs downstream, so they can adjust orders or transportation proactively.

Crucially, digital twins enable predictive and prescriptive SCM. Paired with AI and advanced analytics, a twin can forecast demand spikes, optimise safety stock, or even autonomously adjust production schedules. McKinsey emphasises that digital twins allow companies to move beyond static heuristics to truly dynamic optimisation: “a 360-degree view of profit and cost trade-offs” across products, plants, and markets.

In one case study, a large retailer that linked planning, inventory deployment, and transportation via a digital twin achieved up to a 20% increase in promise-fulfilment and a 10% reduction in labour costs. Another example is a global OEM that embedded a digital twin in its Transportation Management System, cutting freight and product damage costs by roughly 8%.

Moreover, digital twins can augment existing SCM processes without replacing them. They integrate via APIs into ERP and SCM systems, consuming standard master data (SKUs, locations, routes) and sensor feeds. The underlying IT architecture usually only needs a modest increase in compute power; most of the heavy lifting is done by coupling existing software with the twin’s simulation engine. Importantly, experts caution that before launching a twin, organisations must align on data models: consistent nomenclature, calibrated parameters, and clean data pipes. That means strong data governance is critical, one of the biggest challenges noted by practitioners.

In essence, digital supply chain management is about a continuous digital feedback loop: data flows from the physical network into the twin, which then runs analytics and feeds back recommendations (or even executes changes) into operational systems. This not only provides visibility but also drives continuous improvement. For example, a supply chain twin might simulate thousands of replenishment scenarios over the next quarter, learn which strategy minimises stockouts best, and then automatically adjust reorder points in the ERP. Over time, the twin “learns” from each cycle, becoming more accurate. This closed-loop capability is what makes digital twins an engine for smarter, AI-driven supply chain management.

Industry Statistics and Market Insights

The data shows that digital twins and SCM are fast-growing. Industry reports project explosive growth for both digital twin technology and supply chain software:

-

- Digital twin market growth: The overall digital twin market is forecast to jump from $6.9B in 2022 to $73.5B by 2027 (CAGR ≈60.6%). By 2032, global analysts expect it will reach $125–150B. Much of this expansion is driven by demand for digital twins in supply chains and manufacturing.

-

- Supply chain digital twins: Specifically for supply chains, market studies predict growth from about $2.6-2.8B in 2022-2023 to roughly $8–9B by 2033-2034 (CAGR ≈12-13%).

-

- Regional adoption: North America currently leads in digital twin investment (over 30% share), with Europe and Asia growing fast (though this blog focuses on global trends rather than any one region).

-

- Return on investment: Early adopters report significant gains. BCG found that using a value-chain digital twin improved forecast accuracy by 30% and cut delays/downtime by 50-80% in heavy industry pilots. Rolls-Royce cites up to a 50% extension of engine maintenance intervals via engine-twinning, and has saved 22 million tons of CO₂ emissions to date.

-

- SCM and logistics software: Leading SCM software vendors (Oracle, SAP, Kinaxis, Blue Yonder, Llamasoft, etc.) are integrating twin capabilities into their platforms. Gartner notes that by 2025, a majority of large manufacturers will use digital twins in their supply chain risk management processes (for scenario planning and disruption response).

- Digital supply chain use cases: Technologies like IoT, AI, and digital twins are increasingly part of “digital supply chain” strategies. For instance, IBM lists digital supply chain management as an approach using AI/ML and IoT to enhance forecasting, inventory, and logistics. Industries from automotive to healthcare to retail are piloting twins, from virtual warehouses to end-to-end shipment simulations, to stay competitive.

These statistics underline that digital twins are moving from pilot projects into production environments. With strong CAGR and measured ROI, businesses are rapidly scaling digital twin solutions in SCM to get ahead.

Industry Applications and Case Studies

Digital twins are being applied across virtually all sectors of supply chain operations:

-

- Manufacturing & Automotive: In factory floors and assembly lines, twins simulate production processes and maintenance. Example: A leading aerospace manufacturer uses engine digital twins to tailor maintenance per engine, improving uptime and cutting spare-part inventory. Automotive OEMs have developed supply chain twins to dynamically balance production output with shifting demand and supply constraints. These twins can, for example, adjust parts ordering in real time when upstream suppliers have delays. Intellify’s manufacturing clients (and global brands like Boeing or Volvo) use twins for capacity planning and to identify bottlenecks before they occur.

-

- Logistics & Warehousing: Twins give real-time views of warehouses and fleets. DHL, for instance, built a simulation-powered warehouse twin that forecasts picker staffing needs with 98% accuracy. By modelling daily parcel flows and order mix, DHL’s twin (nicknamed the “Crystal Ball”) continuously predicts the optimal number of warehouse workers per shift. This has smoothed throughput peaks and improved on-time dispatch. Similarly, shipping logistics twins connect port, yard, and vessel data to optimise routes. Maersk highlights that real-time AIS data (ship tracking) can feed a global shipping twin, helping shippers choose alternate routes during canal blockages or severe weather.

-

- Retail & E-Commerce: Retailers use twins to simulate customer demand and inventory flow. One retailer case (McKinsey) reported up to 20% improvement in on-time delivery after linking its inventory deployment and transportation twin. Twins help retailers plan promotions by forecasting how price changes or ad campaigns will ripple through factories and distribution. They also play a role in just-in-time replenishment by predicting stockouts and triggering preventive orders. In omnichannel supply chains (B2C and B2B), digital twin software enables rapid scenario testing, e.g., “if website demand jumps 30%, can our replenishment network respond?”, without disturbing live operations.

-

- Heavy Industry (Energy, Oil & Gas, Mining): Complex, global supply chains in oil, gas, chemicals, and construction are a perfect fit for twin modelling. BCG reports that firms in these sectors face “siloed data, reactive analysis and manual bottlenecks”. By deploying a supply-chain twin (often via a cloud AI platform), companies can overcome these issues. For example, a mining company might use a twin to simulate how a port closure in one continent affects critical part deliveries to its mines on another, and then reschedule shipments proactively. Early BCG X clients in energy/chemicals saw inventory levels and capital expenditures drop as their supply chains were optimised by twins.

-

- Construction & Project Supply: In construction supply chains, digital twins are emerging to plan the delivery of materials to sites. Twinning construction equipment and material flows allows project managers to visualise schedules virtually. If a supplier delays concrete or steel, the twin updates show which tasks will slip. Construction SCM software vendors have begun adding twin modules to simulate project timelines and supply orders, improving cost and time estimates. (The Intellify works with building firms to integrate digital twins for construction supply sequencing.)

- Healthcare & Pharma: Hospitals and pharma companies use twins to secure cold chains and manage complex supplier networks. For example, a vaccine manufacturer can twin its entire production and distribution chain, using real-time temperature and location data to ensure doses stay viable. Digital twins also help pharmaceutical companies simulate raw material supply (e.g., reactants) and test responses to regulatory changes. Though still nascent, these use cases are rapidly growing with the demand for visibility in critical product chains.

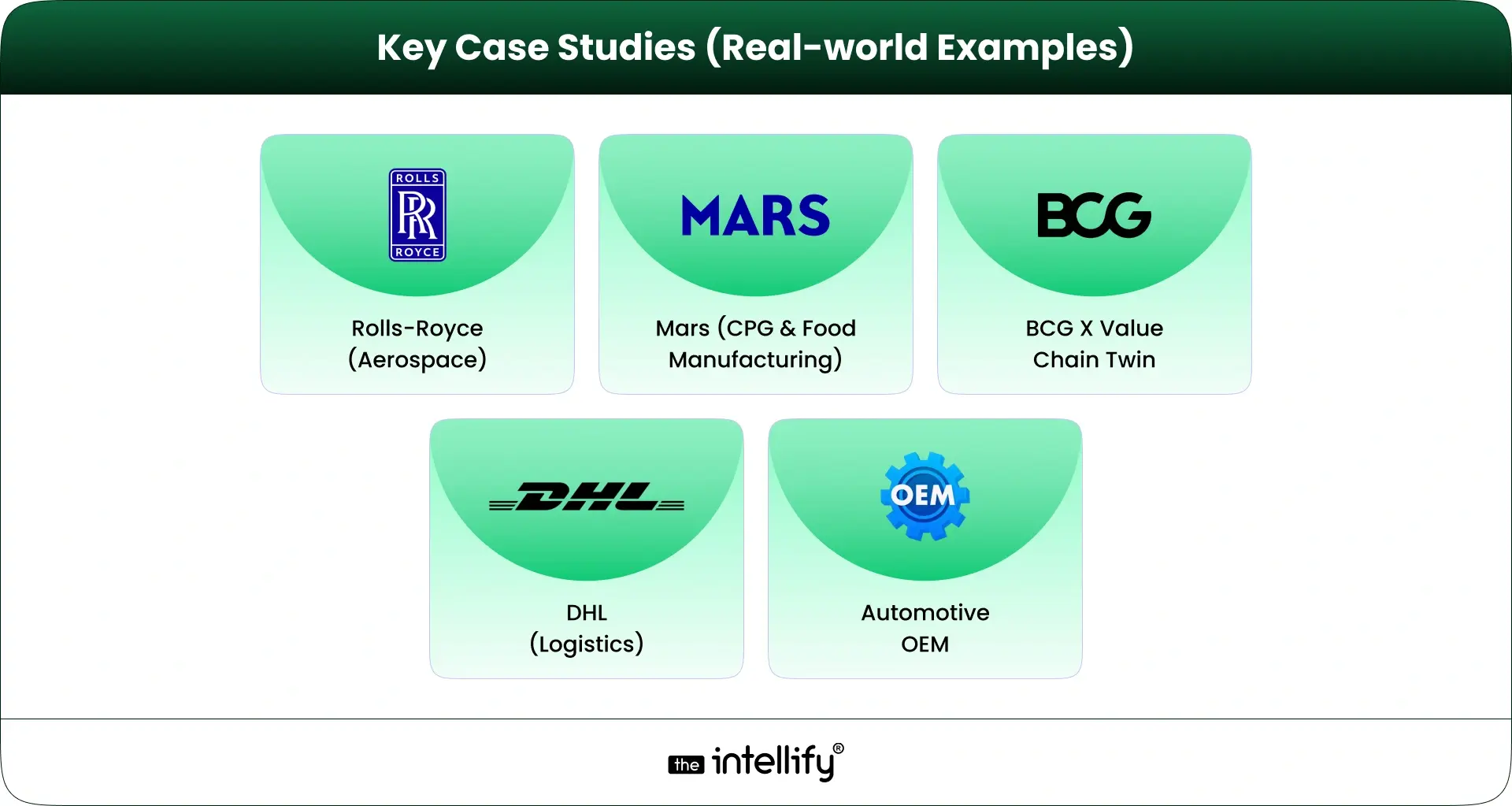

Key Case Studies (Real-world Examples):

-

- Rolls-Royce (Aerospace): Deploys engine digital twins to monitor how each jet engine performs under varying conditions. They’ve extended maintenance intervals by up to 50% and saved 22 million tons of CO₂ through optimised use and fewer part replacements.

-

- Mars (CPG & Food Manufacturing): Created a digital twin of its global manufacturing supply chain using Azure and AI. This twin optimises machine uptime and reduces waste in 160 plants worldwide. Mars reports the twin provides a “virtual app store” of reusable use-cases across its production lines.

-

- BCG X Value Chain Twin: A digital-twin SaaS adopted by industrial clients. Early deployments saw 30% better forecast accuracy and 50-80% fewer shipment delays. One chemical company used the twins’ “digital original” approach: designing virtual supply chains first, then building actual capacity to match.

-

- DHL (Logistics): At a major Brazilian distribution centre, DHL’s simulation twin (built with Simul8) routinely predicts the number of pickers needed to meet demand. This has dramatically reduced resource crunches on peak days (when 20% higher orders occur at month-end).

- Automotive OEM: (From McKinsey) A global carmaker applied a digital twin to its transportation network, yielding about an 8% cost reduction in freight and damage. Another carmaker creates virtual models of its assembly lines to forecast output changes if supply disruptions occur.

These examples demonstrate that digital twins deliver concrete SCM improvements across sectors. They turn what-if planning into automated resilience: companies can visualise entire supplier chain management networks in software, test shocks (like a supplier outage), and adapt policies on the fly.

Governance and Best Practices for Scaling Digital Twins

Successfully scaling digital twins across global SCM software requires careful governance and smart practices. The following principles summarise industry best practices:

-

- Executive Vision & Roadmap: Define a clear “North Star” for your supply chain twin program. McKinsey advises setting a future-state vision and prioritising use cases by impact. Early wins (low-hanging fruit) build credibility. Create a roadmap that links digital twin use cases with business goals (e.g., reduce stockouts, cut lead times).

-

- Data Governance & Quality: A digital twin is only as good as its data. Ensure consistent data standards and master data management across ERP, MES, WMS, and third-party sources. This may involve creating shared data definitions (e.g., unified product codes), cleansing legacy data, and implementing an enterprise data catalogue. Maersk warns that “consistent data quality, standardisation, and governance practices” are critical for an accurate virtual model. Plan for data pipelines (IoT feeds, EDI messages, APIs) that feed the twin in near real-time.

-

- Integrated, Modular Architecture: Digital twins should build on existing SCM systems, not replace them. Use open APIs and middleware to stitch together ERP, SCM, and IoT platforms. The twins’ compute can often run in the cloud, scaling with demand. Ensure your IT teams have the flexibility to add processing power (e.g., cloud servers) as needed. Avoid siloed solutions: as CIOs note, a twin breaks down silos by acting as a centralised “single system of record” for planning and operations. This integration enables holistic optimisation of building management systems, logistics, or manufacturing processes as one coherent whole.

-

- Cross-Functional Teams: Use agile, cross-disciplinary teams to develop the twin. Bringing together supply planners, data scientists, IT architects, and operations managers prevents the common pitfall of “departments working in isolation”. Leadership must champion the change. Deloitte stresses that building digital twins requires cultural shifts: processes and roles will change, so invest in change management and training. For example, train planners to trust twin-generated insights, and equip IT to support iterative development.

-

- Talent and Skills: Assess and fill skill gaps. Effective twin teams need product managers, data engineers, ML/AI experts, and system integrators. According to McKinsey, personnel with agile methodology experience (sprint planning, Scrum) can accelerate value delivery. Consider upskilling existing SCM staff on analytics, or hiring specialists in cloud and twin platforms (e.g., Azure Digital Twins, Siemens MindSphere).

-

- Iterative Pilots & Simulation: Don’t boil the ocean. Start with one business unit or geography as a pilot use case. Quickly develop a minimum viable twin that plugs into key data sources. Relex Solutions warns that impatience leads to unrealistic expectations. Instead, adopt a “fail fast, learn fast” approach: build a simple simulation of one end-to-end process (e.g, one product line or warehouse), validate its output, and refine. As results accrue, expand the twins’ scope. McKinsey suggests building analytics modules (optimisation, simulation) on the data incrementally. Teams can even start developing advanced simulations before all data is perfect, capturing early wins to demonstrate value.

-

- Robust Risk & Security Controls: Scaling globally means more exposure. Secure the digital twin just like any critical system: encrypt data in transit, authenticate access, and segment networks. Maersk highlights that synchronising digital twins with physical assets demands cybersecurity measures to protect sensitive supply chain data. Additionally, adhere to compliance/regulatory requirements for data sharing (especially with international partners). A governance board or steering committee can oversee these policies.

-

- Break Down Silos and Collaborate: Use the twin to foster supply chain collaboration. As a centralised platform, it enables sales, operations, procurement, and logistics teams to see the same data. Promote cross-departmental dashboards and alerts (e.g., a live supply chain “flight tracker”) so all stakeholders can coordinate actions. Encourage external collaboration by sharing a sanitised version of the twin with key suppliers or carriers (under data-sharing agreements) to increase transparency.

-

- Monitor and Iterate: Finally, treat the digital twin as a live product. Continuously measure its performance using KPIs (forecast error, service levels, cost savings). Leadership should regularly review insights from the twin and update policies accordingly. If the twins’ forecasts deviate, adjust models. If new disruptions emerge, incorporate them into scenarios. This feedback loop ensures the twin stays accurate and valuable over time.

By following these best practices, organisations can avoid common pitfalls (like expecting instant magic) and ensure that digital twins truly scale as a core part of SCM.

Conclusion & Next Steps

Digital twins have leapt from science fiction to present-day supply chain strategy. As Deloitte succinctly puts it, they are “not the future of supply chains… they are the present”. With today’s cloud platforms, abundant data, and AI tools, the barriers to implementation are lower than ever. The key is to apply them wisely: define clear goals, manage data and change diligently, and integrate with existing supply chain management tools. When done right, digital twins transform supply chains into agile, transparent networks that adapt on the fly to disruptions. The evidence is strong: companies report significant reductions in costs and delays, and improvements in service levels and sustainability.

In summary, Scaling Digital Twins Across Global SCM Software is a journey of technology, governance, and best practices. It blends all aspects of supply chain management, from procurement and warehousing to logistics and risk management, into a living model that decision-makers can trust. For organisations seeking to lead rather than follow, investing in digital twins now will pay dividends in resilience and competitiveness.

Why The Intellify

The Intellify is a leader in AI-driven supply chain solutions, specialising in digital twin technology. Leveraging our expertise in advanced analytics and industry software, we build and integrate custom digital twin models into existing SCM platforms. Our team helps clients in automotive, healthcare, manufacturing, and other industries implement the best governance, data management, and optimisation practices for scalable supply chain twins. With Intellify, businesses gain not only cutting-edge supply chain management software but also a partner who ensures end-to-end visibility, robust risk management, and continuous improvement. Trust The Intellify to guide your journey to a smarter, more resilient supply chain.

Most Asked FAQs

1) What is a digital twin, and how does it work in supply chain management?

A: A digital twin is a dynamic virtual replica of a physical asset, process, or system; in supply chain management, it mirrors inventory, transport, and supplier networks using live data to simulate outcomes.

2) How does a digital twin improve supply chain risk management and resilience?

A: By simulating disruptions across supplier, transport and inventory layers, a twin helps quantify impacts and identify alternate actions before events occur.

3) Which supply chain management software and digital twin platforms support digital twinning?

A: Leading platforms include cloud twins (Azure Digital Twins, AWS IoT TwinMaker, Google Cloud building blocks), industrial suites (Siemens, PTC/ThingWorx) and enterprise suites that integrate twin modules (Oracle, SAP).

4) How do you scale a digital twin across global supply chain management systems without breaking existing SCM software?

A: Scale incrementally: start small (pilot lane/plant), standardise data models, use API middleware, and iterate, don’t replace core ERP/WMS/TMS.

5) What data, telemetry and integration requirements are needed to build a supply chain digital twin?

A: You need master-data (SKUs, routes, locations), real-time telemetry (IoT, GPS), transactional feeds (ERP/WMS/TMS), and robust pipelines (streaming + batch) with schema contracts.

6) What are realistic ROI expectations and cost drivers for the digital twin in SCM?

A: ROI varies; pilot winners commonly report improved forecast accuracy, lower inventory and fewer delays, many cite measurable service/cost gains within 6-18 months.

7) Can digital twins integrate with ERP/Oracle/SAP supply chain management software, or do they require replacing ERP?

A: They integrate twins, usually augment ERP/SAP/Oracle by reading master and transactional data and writing back recommendations; replacement is rarely required.

8) How do AI and machine learning enhance a digital twin (what is an AI digital twin)?

A: AI/ML turns twin simulations into predictive and prescriptive systems, predicting failures, optimising inventory and recommending actions automatically.

9) What governance, security and compliance controls are essential for supply chain digital twins?

A: Key controls: data ownership, RBAC, encryption (at-rest/in-transit), data contracts, model validation, and audit trails for decisions.

10) What are practical digital twin examples in manufacturing, logistics and healthcare?

A: Examples: factory line twins for predictive maintenance; warehouse twins for staffing/throughput optimisation; pharma cold-chain twins for temperature and traceability control.