Summary:

AI inventory management software is reshaping how businesses handle stock, forecasting, and daily operations. Instead of relying on guesswork or outdated spreadsheets, AI helps companies track inventory in real time, spot trends early, and prevent stockouts or excess stock. This blog explains how AI improves accuracy, lowers costs, and boosts overall efficiency across retail, e-commerce, manufacturing, logistics, and more while helping teams work smarter and make better decisions every day.

Why Inventory Management Still Feels Complicated

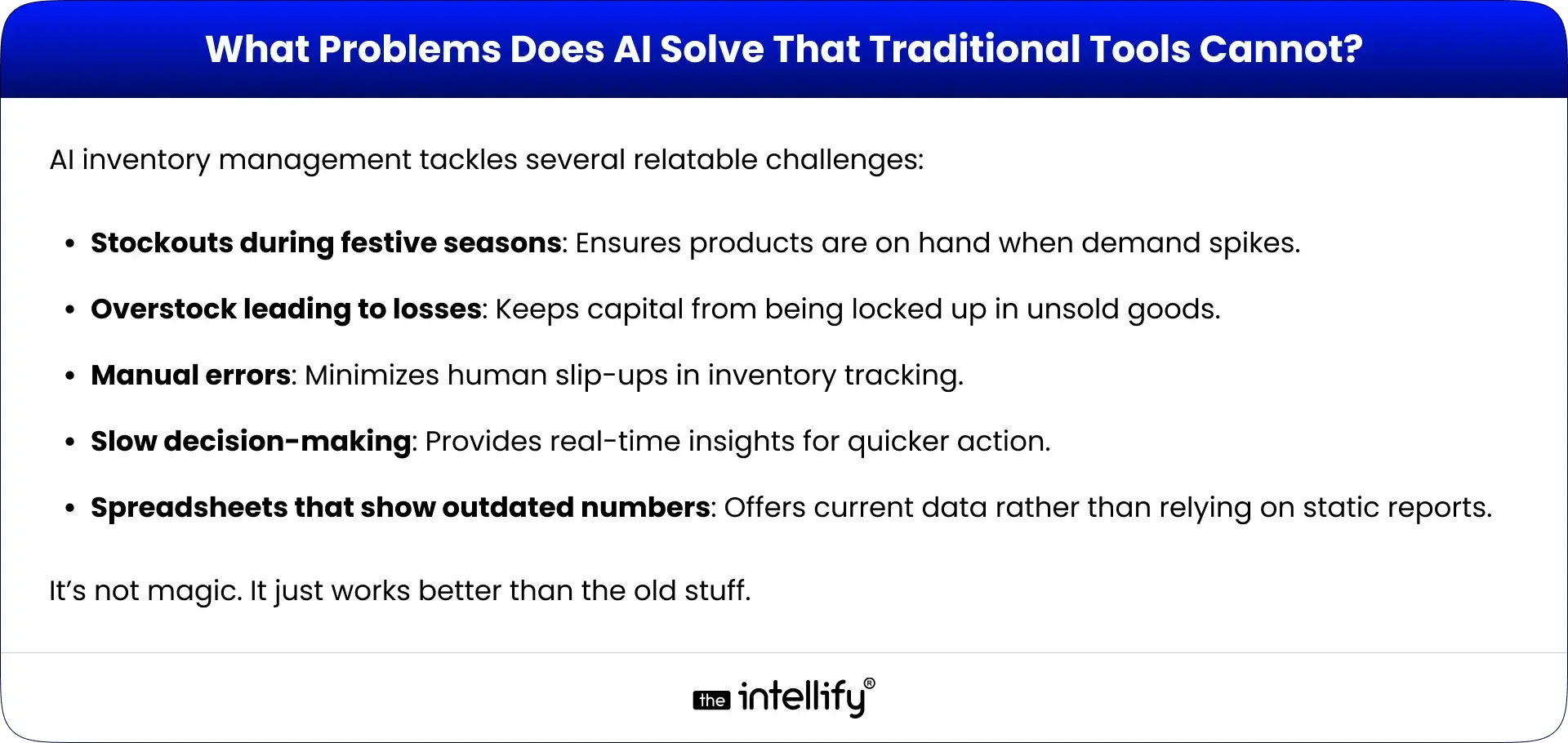

Let’s be honest, managing inventory today can feel like walking into a storeroom where someone turned off the lights and moved everything around. Even with all the so-called “modern tools,” businesses still deal with the same old headaches: stockouts at the worst possible time, piles of unwanted stock gathering dust, and those tiny manual errors that somehow snowball into big problems. Add unpredictable demand on top of that (think festival rushes or random social media trends), and the whole thing becomes exhausting.

That’s where AI inventory management software steps in, not as another shiny tech toy, but as something that genuinely helps untangle the mess. Think of it as that calm friend who walks in, switches on the lights, and says, “Alright, let’s figure this out.”

In this blog, we’ll walk through how AI inventory management can simplify everyday operations, improve decision-making, and yes, give your business a better shot at healthier profits.

What Is AI Inventory Management Software?

AI inventory management software basically works like a super observant assistant, the kind who notices everything you miss. Instead of juggling spreadsheets, sticky notes, and gut feelings, AI looks through heaps of data, catches patterns you didn’t know existed, and quietly automates a lot of repetitive tasks.

Most traditional systems are reactive. They wait for something to go wrong before telling you. AI, on the other hand, uses real-time information from sales, suppliers, and market shifts to stay one step ahead. You get fewer mistakes, faster insights, and a much clearer picture of what’s happening across your business.

How AI Inventory Management Works Behind the Scenes

It might sound complicated, but the behind-the-scenes process is actually pretty logical:

- Data Collection: AI pulls info from everywhere: sales numbers, supplier updates, market changes. Kinda like someone reading all the notes you left scattered around the office.

- Pattern Recognition: It checks for patterns and weird bumps in the data. (Think of that moment when you sense something’s off but can’t quite explain it AI can explain it.)

- Demand Forecasting: Based on history and trends, AI guesses what you’ll need next. And it’s usually right… eerily right sometimes.

- Real-Time Stock Analysis: Your inventory gets monitored like a live dashboard, not a once-a-week task.

- Automated Decisions & Alerts: If something’s running low, AI pings you. If something’s piling up, it pings you again. It’s a bit like having a persistent but helpful assistant.

- Integration: It syncs smoothly with ERP, WMS, POS, eCommerce tools, basically everything that keeps your business running.

Key Features of AI Inventory Management Software

When you’re looking for a solid AI inventory management software, here’s what actually matters:

- Smart demand forecasting: Adjusts inventory levels based on real patterns.

- Automated purchase ordering: Takes repetitive reordering off your plate.

- Multi-location visibility: Lets you see what’s happening across all your sites at once.

- Stockout & overstock prevention: Sends alerts before issues become expensive.

- Real-time dashboards: Give you a snapshot of what’s happening right now.

- Supplier performance insights: Shows who’s reliable and who’s… not.

- Workflow automation: Cuts down manual tasks so your team can breathe.

- Expiry/seasonal trend alerts: Helpful when managing perishable or seasonal items.

- AI-driven SKU-level insights: Breaks things down to the tiniest level so nothing gets overlooked.

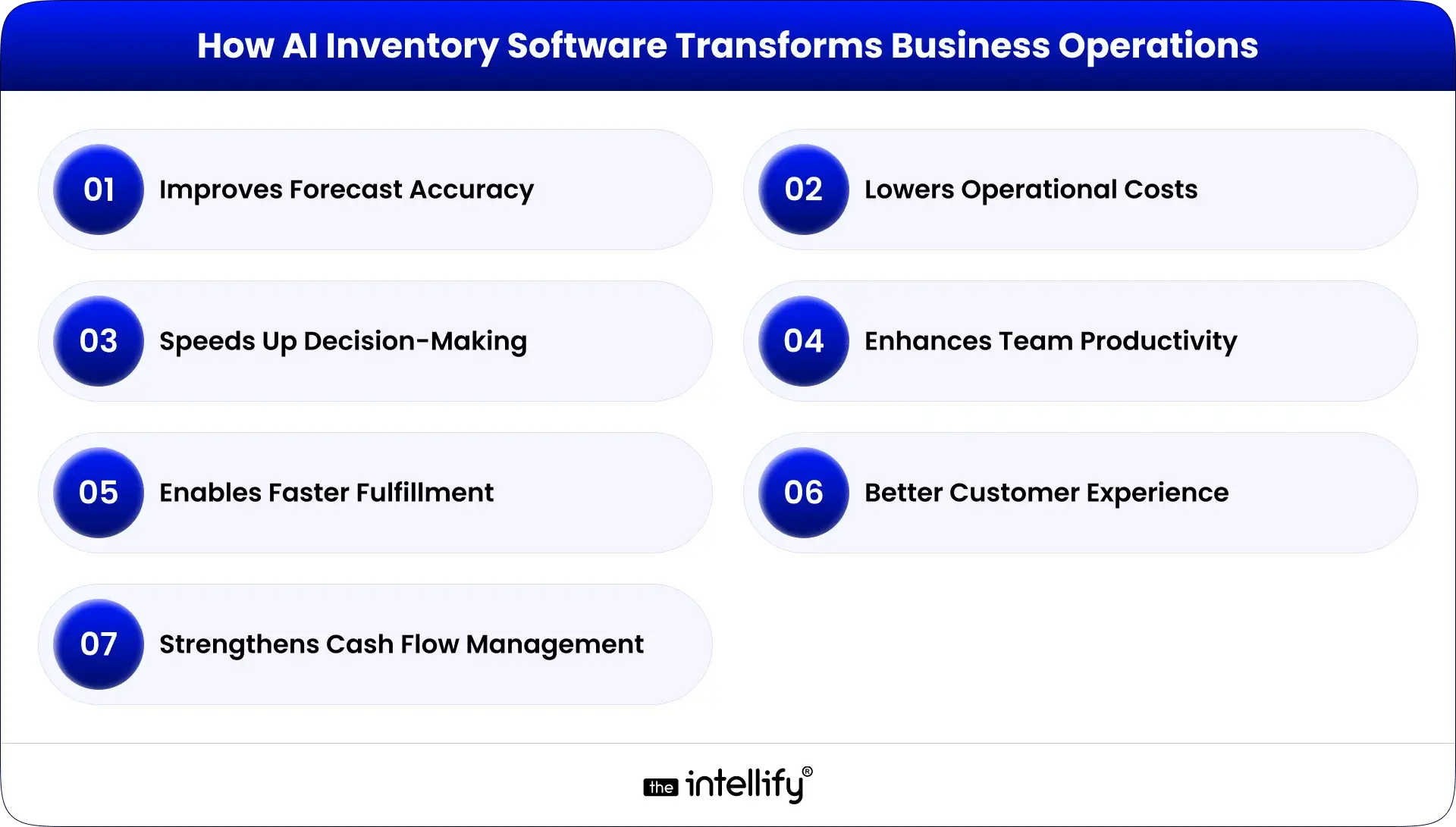

How AI Inventory Software Transforms Business Operations

Improves Forecast Accuracy

With AI, you’re not guessing. You’re working with clear patterns and data that actually makes sense. No more “I think we might need this?” moments.

Lowers Operational Costs

From smarter reordering to better storage planning, costs naturally shrink because you’re no longer buying too much or too little.

Speeds Up Decision-Making

No more waiting around for someone to update a spreadsheet. AI gives insights right when you need them.

Enhances Team Productivity

AI handles repetitive tasks. Teams get to focus on actual strategy instead of counting boxes or fixing typos.

Enables Faster Fulfillment & Better Customer Experience

Real-time sync means orders move faster, customers get updates sooner, and things just… run smoother.

Strengthens Cash Flow Management

By buying only what you really need, you avoid freezing money in unnecessary stock.

AI Inventory Management vs Traditional Systems

| Feature | Traditional Systems | AI Inventory Management |

|---|---|---|

| Accuracy | Often prone to errors | Highly accurate due to data analysis |

| Speed | Slower response times | Instant reporting and alerts |

| Cost | Higher storage costs | Reduced storage and operational costs |

| Automation | Manual processes | Automated alerts and actions |

| Scalability | Limited | Easily scalable to fit business growth |

| Business Impact | Reactive strategies | Proactive, data-driven approaches |

Real-World Use Cases: AI Inventory Software Across Industries

Retail & Supermarkets

- Seasonal forecasting: Adjust stock levels during holidays and special events.

- Shelf availability: Ensure popular items are always on hand.

- Reduce spoilage: AI tracks expiration dates, helping minimize waste.

E-commerce & D2C Brands

- Multi-warehouse syncing: Distributes stock effectively across different locations.

- Prevent overselling: Real-time alerts help avoid running out of stock.

- Faster fulfillment: Streamlined operations mean quicker delivery times.

Manufacturing

- Raw material planning: AI anticipates material needs, optimizing the supply chain.

- Production scheduling: Alters manufacturing schedules based on stock levels.

Logistics & Warehousing

- Slotting & space optimization: Organizes warehouse inventory for easy access.

- Faster inbound/outbound planning: Improved planning leads to more efficient operations.

Healthcare & Pharma

- Track expiry-sensitive inventory: Manages vital medical supplies effectively.

- Maintain essential stock levels: AI keeps critical items readily available.

Automotive & Spare Parts

- Complex SKU forecasting: Effectively handles a diverse range of spare parts.

- Reduce aging inventory: Avoids unnecessary costs related to surplus parts.

How to Choose the Right AI Inventory Management Solution

When picking the best software for your needs, keep these key factors in mind:

- Scalability: Ensure the solution can adapt as your business grows.

- Industry fit: Opt for software designed for your specific sector.

- Ease of integration: Seek solutions that easily synchronize with your current systems.

- Accuracy of forecasting: Prioritize options that excel in reliable predictive capabilities.

- Support & training: Make sure you have the resources to utilize the software fully.

- Customization: Tailored features can make a significant difference.

- Vendor expertise in AI: Partnering with a knowledgeable vendor enhances your implementation experience.

How Much Does AI Inventory Management Software Cost?

Costs can range widely based on several factors:

- SaaS subscription: Monthly fees for cloud-based solutions.

- Custom software pricing: Tailored solutions typically come at a higher cost.

- Integration cost: Additional expenses to connect with existing systems.

- Additional features: More advanced tools may carry higher price tags.

- Maintenance: Costs for ongoing support services.

- Factors that affect pricing: Complexity, industry-specific features, and scale play a role in overall cost.

Future Trends: Where AI Inventory Management Is Heading Next

Some pretty interesting trends are emerging:

- Autonomous inventory: Systems that manage stock independently.

- AI agents managing supply chains: AI systems taking complete control of supply logistics.

- IoT + AI warehouse intelligence: Smart warehouses that leverage real-time data for optimization.

- Zero-touch replenishment: Solutions that reorder stock automatically without human input.

- Generative AI for reporting: AI that quickly generates comprehensive reports with ease.

Why Partner With The Intellify for AI Inventory Management Solutions

At The Intellify, we stand out with our expertise in AI inventory management software. We provide:

- Proven success shown through detailed case studies.

- Custom AI development services tailored to your specific business needs.

- Comprehensive support to guarantee a smooth implementation.

- Scalable solutions, ready to evolve with your organization.

If you’re ready to simplify the messy parts of inventory, we’re here to help.

Conclusion

AI inventory management software isn’t just another trend. It’s becoming the backbone of how modern businesses operate. With better forecasting, lower costs, and faster decisions, it opens the door to running things more smoothly, and companies can gain a competitive edge.

If you’re ready to step into this new way of working, The Intellify is happy to guide you through it.

Frequently Asked Questions (FAQs)

1. What does AI inventory management software do for businesses?

It basically keeps an eye on your stock so you don’t have to hover over spreadsheets all day. It tracks what’s moving, what’s sitting, and what’s about to run out. The goal? Fewer surprises, smoother routines, and way less “Wait… how did we miss this?” moments.

2. How does AI make inventory forecasting more accurate?

AI looks at past sales, trends, and a bunch of small patterns people usually miss. It connects dots quickly and gives you a clearer idea of what’s coming next. No guesswork. No crossed fingers. Just cleaner predictions that make planning feel less stressful.

3. Can AI help prevent stockouts and overstocking?

Yep, that’s kinda its thing. It sends alerts when something’s running low or piling up. Think of it like a polite nudge, you know, the kind that saves you from last-minute rush orders or shelves stuffed with products nobody touched for weeks.

4. What key features should AI inventory software include?

Look for the basics that actually make life easier: forecasting, auto-reorder alerts, real-time dashboards, and visibility across all your locations. Nothing fancy, just the stuff that keeps your inventory in check without constant babysitting.

5. Does AI inventory software integrate with ERP, WMS, or eCommerce tools?

Most modern ones do. They plug into whatever you already use, so everything stays synced. No double work. No “Oops, wrong numbers again.” Just smoother workflows that feel… well, normal.

6. Is AI inventory management suitable for small businesses?

For sure. Small teams actually benefit a lot because AI takes care of the repetitive stuff. If you’re tired of juggling too many tasks or fixing small errors that add up, AI can lighten that load without making things complicated.

7. How much does AI inventory management software cost?

There’s no one price. It can be a simple monthly subscription or a custom setup that costs more, depending on what you need. Features, integrations, and the size of your business all play a role. Basically, it depends, but you can usually find something within reach.

8. Why choose The Intellify for AI inventory management solutions?

We build systems that fit your business, not the other way around. The Intellify brings real hands-on experience, clear communication, and support that doesn’t vanish after launch. If you want something that actually works day-to-day, we help you get there without the drama.